Quite simply put – yes we can! Low enthalpy-based power generation has recently seen a number of new entrants into its research and development sphere – strongly reaffirming its untapped potential.

Couple this with growing climate concerns – it seems the time has never been better to serve a growing energy need worldwide.

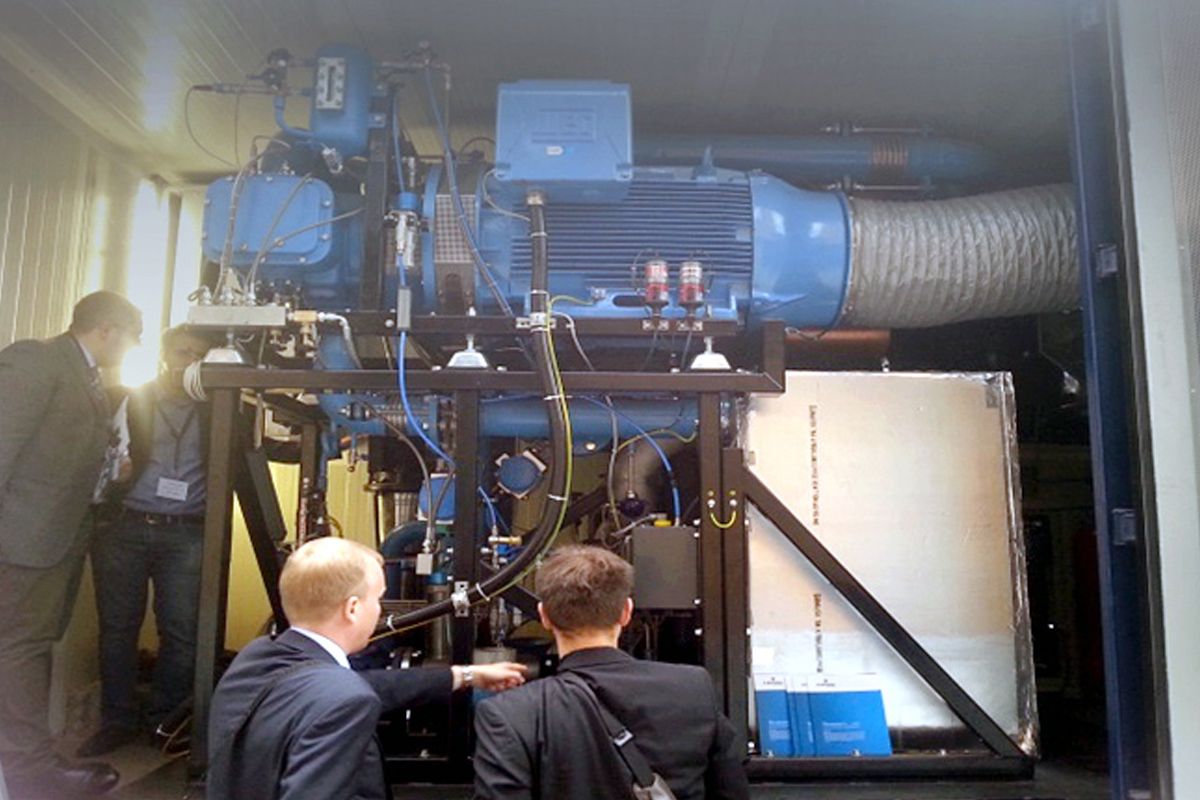

At HERA, we’ve always felt that our members stood to gain a lot from embracing and being part of this technology’s progression, and recently attending the Organic Rankin Cycle (ORC) Conference in Belgium – we feel even more so. Having the opportunity to see products from new entrants and the level of technology displayed confirms New Zealand has every capability to become a competitive part of this revolution ticking quietly away in the background.

Having the opportunity to see products from new entrants, the level of technology displayed confirms New Zealand has every capability to become a competitive part of this revolution ticking quietly away in the background.

So where do you fit in?

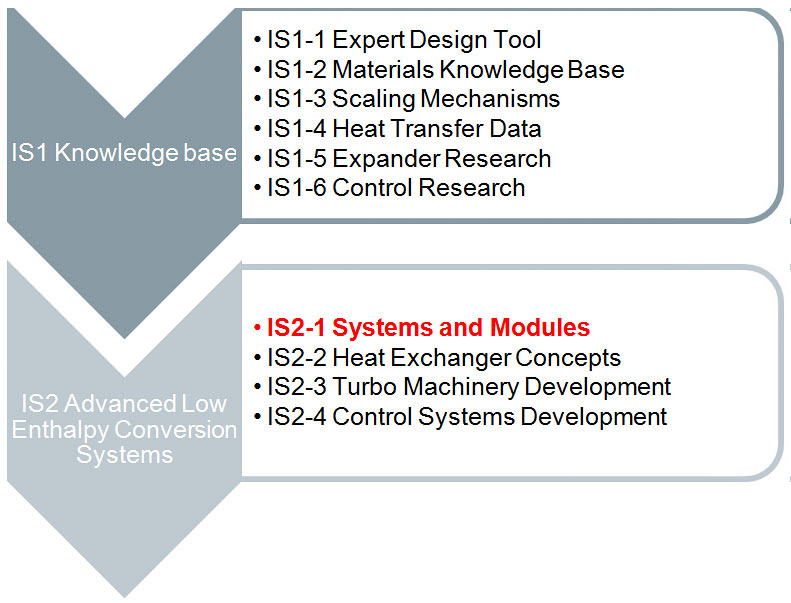

We created the AGGAT program to support the development of compact, modular, highly efficient ORC power plants – and since its inception, we’ve had a number of our member companies and end-users engage with us as a means to strategically enter international markets competitively in the future.

So far, we’ve done extensive work in phase one of our program (IS1), and currently are focused on IS2-1, which sees the completion of our members’ ORC pilot plants for demonstration and potential sale.

Our programme is now on track to deliver two ORC pilot plants – one using a waste heat source and the other relying on low temperature geothermal brine for heat provision. It’s a testament to a collaborative environment supporting our programme partners to secure a heat source, extensive fabrication works, technology development and implementation of the technology transfer process. It’s expected that, with our technical support, one of these plants will be ready for the commissioning phase in the next month, following final works on cooling system installation.

A couple of sub-projects are also underway in collaboration with the University of Auckland for integration within the waste heat ORC pilot plant, looking at:

• Exhaust gas heat source inlet temperature control to constrain high wall temperature influence on binary fluid decomposition rate, and

• Process control system package installation based on ORC control loop models designed in the Chemical Engineering department at the University of Auckland.

How can HERA help?

Our team’s focus on cost-effectiveness has allowed us to be able to investigate several areas of interest for this programme, including alternate heat transfer loop cycles, conducting temperature sensitivity analyses on cycle performance and looking at expected power output performance through turbine design and modelling activities. We’ve created a significant body of data arming our project partners with the information needed to develop robust and competitive products for the market.

Leveraging our strong relationships with our UK-based contacts, we’re now in the process of securing a cost-effective and suitable turbine to assist our members in getting their product to market and are near finalising process model-based outcomes to help justify our case for overseas turbine procurement for the ORC plant.

We’re consistently identifying R&D prospects for our members, and our roadmap process is specifically designed to provide each programme participant a way to enter the market with their own niche offer – so all can benefit from a common research base.

Feel like you’ve missed the boat to opportunity?

Absolutely not! We’d like to know your views on our research objectives in our AGGAT Research Roadmap, HERA Report R5:47, and most importantly – if there’re any areas you’d like to get involved with.

Request a copy of our Report today from our library or if you’d like more information about how we can help you, please contact HERA Senior Research Engineer Dr Boaz Habib.