The Aotea Event Centre was a well selected venue to the second Steel Innovations Conference during Metals Week held on the 1 – 4 September.

First launched in 2013, the biannual Steel Innovations Conference provides a forum for structural engineers, steel industry representatives, academics and students to share the latest knowledge in the design and construction of steel structures.

Key topics of the two-day conference included seismic engineering, composite steel construction, fire engineering, durability, sustainability, cost-effective design and stability.

Delegates learned about the latest innovations in damage-avoidance technology, fire engineering, standard developments and recent major New Zealand and Australasian building projects together with their structural engineering challenges.

High ranking local and international structural steel design experts were the keynote speakers in the morning sessions followed by presentations in two streams in the afternoon. Altogether 45 papers were presented within the conference program.

Our overall impression from the conference is that widely-applied research activity with implementation in practice takes place in many fields. From HERA’s Structural Systems work perspective, certainly the fire design-related work was of high importance as we have dealt with advanced assessment of several structures over the years.

These are paper number 28 Limit Capacity of Edge and Corner Composite Slabs in Fire Conditions (Linus Lim) and paper number 29, Structural Fire Design for Steel-Framed Car Parks (Antony Abu).

HERA Structural Systems staff also co-authored five papers, with Dr Stephen Hicks presenting two of them. The published papers will be freely available to download from the SCNZ website in the coming weeks.

We’re also had our General Manager Welding Centre Dr Michail Karpenko present his paper on brittle fracture assessment of seismic connections using a modified BS 7910 approach.

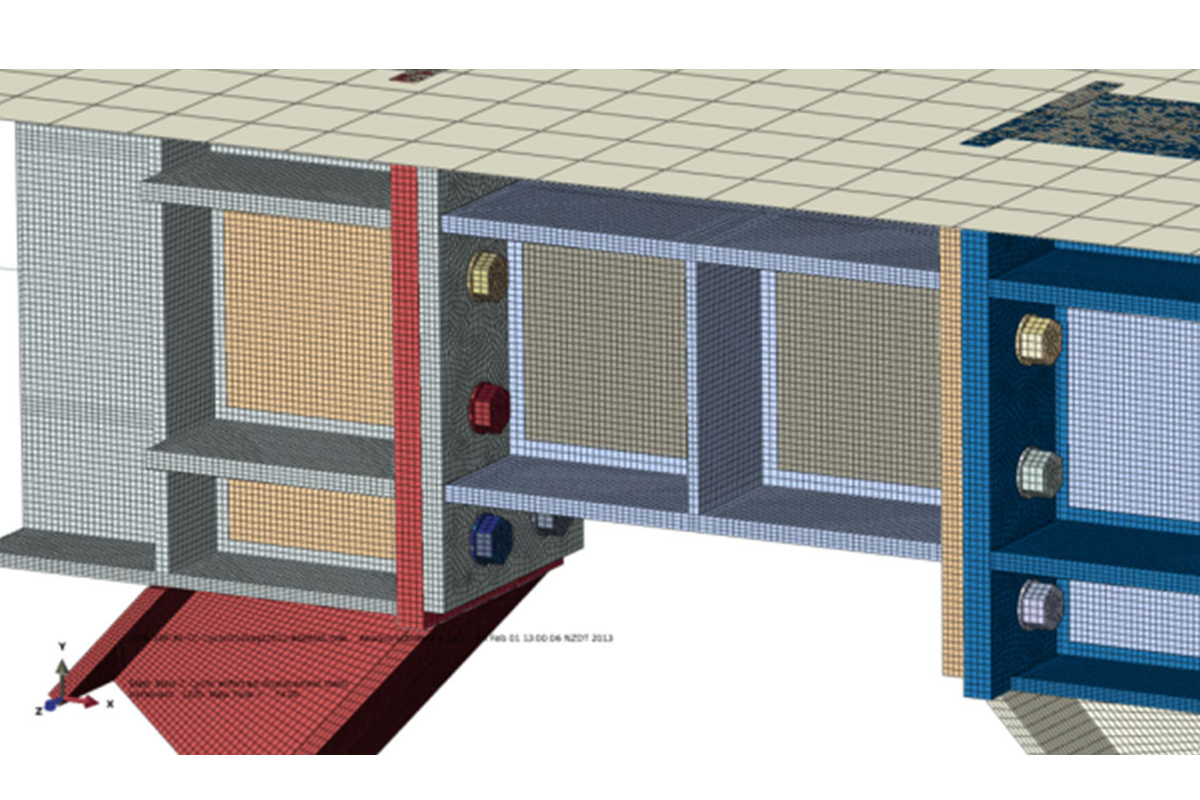

This paper discusses a simplified engineering assessment procedure to evaluate the risk of brittle fracture in welds in seismic steel connections as typically used in New Zealand.

The approach is based on the modified BS 7910 Level 2A procedure that includes a shift in the transition temperature due to the strain hardening introduced by high-strain cyclic loadings. The procedure was used to assess the critical crack size in an active link application as well as in some representative examples of seismic moment connections.

Conclusions were made with respect to the critical crack seize as a function of material properties, service temperature, strain hardening and other critical factors.