Flame, plasma and laser cutting are widely used in industry. The selection of the cutting process is based on the type of material, economic considerations and quality requirements. Despite some specifics, high quality results are obtainable using all of the cutting processes.

The level of quality required for cut surface is determined by the application and its service conditions. Defects generally arise through incorrect cutting procedure and equipment maintenance. Recommended quality requirements are given in WTIA Technical Note 5 for flame cutting applications.

For applications with predominantly static loading, the quality of cut surface is specified to suit subsequent coating application or aesthetic criteria. Grinding may be required to achieve the quality level required.

Grinding is not normally required for carbon steels as light oxide on the surface and minor changes in chemical composition and metallurgy of the cut edges do not affect quality of subsequent welding under normal circumstances.

AS/NZS 1554.1 requires that surfaces to be incorporated in a weld shall not have a surface roughness greater than Class 3 as defined in WTIA Technical Note 5. For flame-cut surfaces being incorporated into the weld, it is considered good practice to lightly grind the cut faces to remove the carbide surface layer.

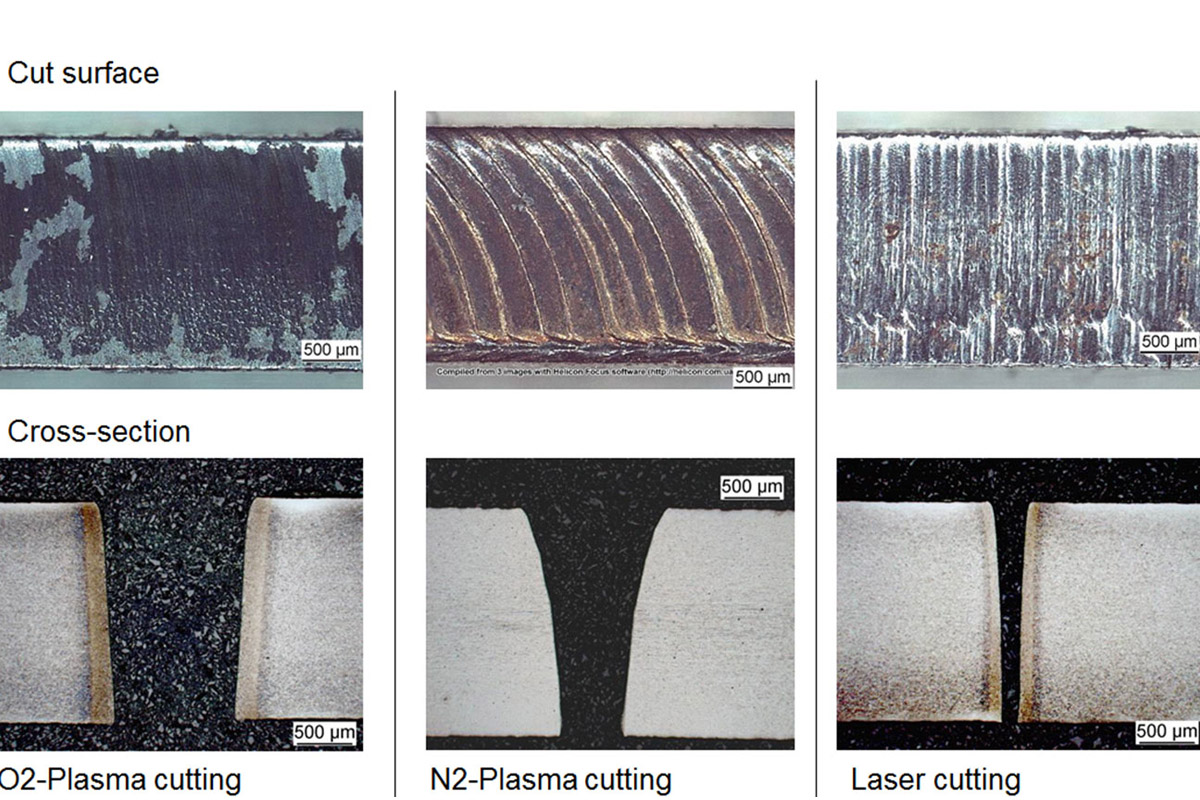

For applications subject to fatigue loadings, the geometry and quality of thermal cut surfaces are the most important factors concerning the fatigue strength. Especially important is the condition of the upper edge, lower edge and cut surface due to the stress concentration in these areas.

There is normally a hardness and gradient in the first millimetre of material from the cut edge. The zone of any excess hardness is normally less than this, depending on the cutting process.

Design and product standards include specific requirements to control some of the parameters critical for the product performance of cut surface. Requirements are given in applicable product standards.

Fatigue-related acceptance criteria for cut surfaces can be found in AS 5100.6 Bridge design Part 6: Steel and composite construction, D1.5 Bridge Welding Code and BS 5400 Concrete and Composite Bridges Part 10: Code of Practice for Fatigue.

AWS D 1.8 Structural Welding Code Seismic Supplement requires the weld access hole finish to have a surface roughness of not more than 13 μm. AWS C4.1, Sample 4, may be used as a guide for evaluating surface roughness of these surfaces.

International standard ISO 9013 Thermal Cutting – Classification of Thermal Cuts introduces quality and tolerance classes for thermal cuts. It superseded the German standard DIN 2310 Thermal cutting part 1 to 6 that was the most comprehensive in the field. According to ISO 9013 the following criteria can be specified:

- Perpendicularity and angular tolerances

- Mean height of the profile (Rz5)

- Dimensional tolerance class

EN 1090-2 Execution of Steel Structures and Aluminium Structures Part 2: Technical Requirements for Steel Structuresspecifies required quality classes depending on the execution class (EXC) of the steel structure.

According to NZS 3404.1:2009, maximum surface roughness shall be 12μm and 25 μm for fatigue detail category ≥ 80 MPa and ≤ 80 MPa respectively. Structural element members (yielding regions of category 1, 2, or 3) subject to low cycle (seismic) fatigue require maximum roughness of 12μm. Roughness values may be estimated by comparison with surface replicas, such as the WTIA Flame Cut Surface replicas.

For structural steelwork specification should require that “Quality of cut surfaces shall be in accordance with NZS 3404.1 and AS/NZS 1554.1”.

According to AS/NZS 1554.6 Structural steel welding. Welding stainless steels for structural purposes structural, edges which have been thermally cut (plasma or laser) will exhibit reduced corrosion resistance.

For these edges to achieve their optimum corrosion resistance they must have the damaged material removed by grinding, ideally followed by pickling. The standard is not specific with respect to quantitative acceptance criteria.

Update shared by our General Manager Welding Centre Dr Michail Karpenko & Senior Welding Engineer Alan McClintock