Every day, we’re driven to solve our members problems. So, when the opportunity to work with Steel & Tube came up to help develop their new construction product – we jumped!

We spent 18 months driving R&D focused on getting their new composite slab product ComFlor SR market ready. Providing design of the test specimens, management of international laboratories, and evaluation of design values from tests in both normal and fire conditions.

The result?

A new type of floor system to the New Zealand market that gives confidence to specifiers because its undergone rigorous testing and evaluation.

As well as the implementation of SCI, UK evaluated design values into a new version of the market leading ComFlor design software to rapidly speed up use and adoption by designers.

Why the move for composite construction?

Composite construction is continuing to gain market share due to the strength and stiffness it can achieve with minimum use of materials.

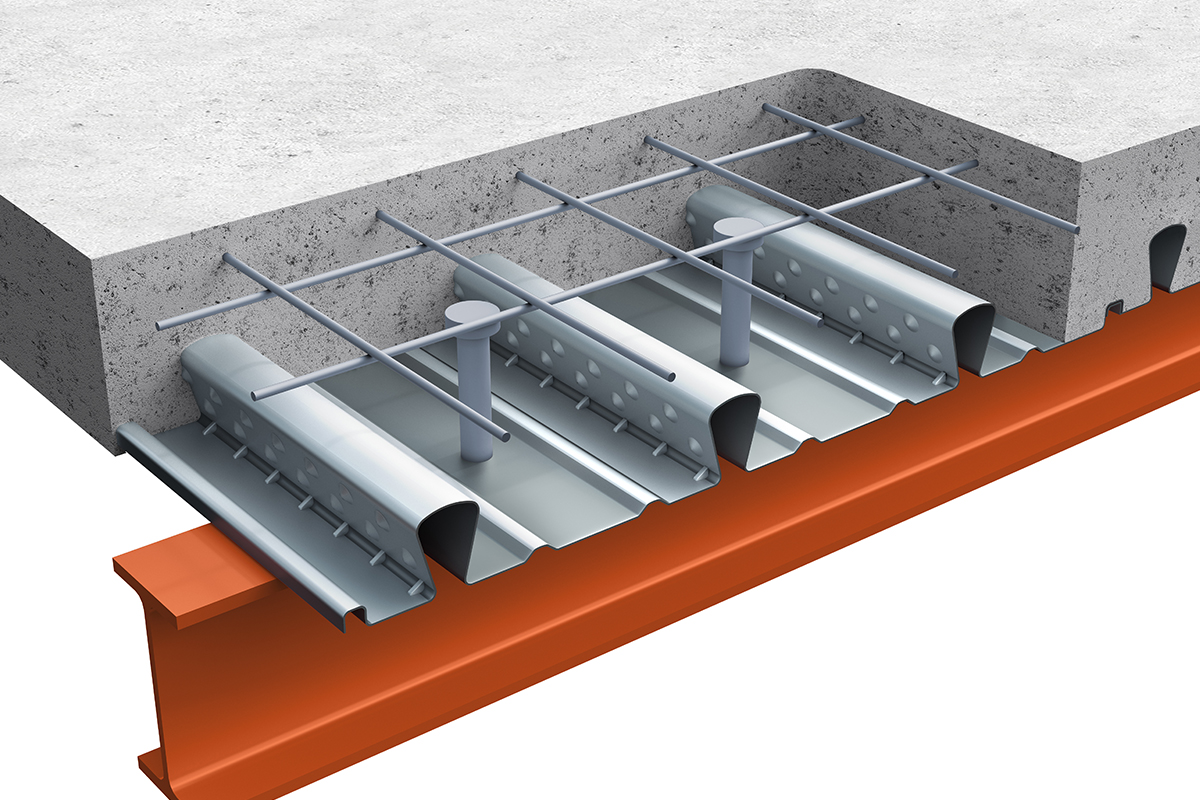

Composite slabs have the following additional benefits:

- Profiled steel decking acts as a safe working platform and permanent formwork, which increases the speed of construction,

- Unpropped construction may be achieved, removing the need for temporary props,

- The decking can stabilise beams during construction, and

- The decking can provide all, or part, of the main tension reinforcement to the slab.

Although re-entrant decks have been used in Europe for some time, New Zealand hasn’t had this type of profile available.

Our members Steel & Tube recognised this as an opportunity ripe for the picking. Setting out to develop a cross-section that would provide a profile that’s inter alia (a flat soffit); with thinner slabs. Their hopes – that it would enhance fire performance and improve vibration and acoustic performance due to its larger mass. It just needed to be proved!

ComFlor SR fell outside the scope of current design standards such as AS/NZS 4600 or EN 1993-1-3 and required key design capacities to be obtained through laboratory tests, advanced numerical modelling, first principal based mechanical analysis such as Improved Engineering Method (IEM) and rigorous structural reliability analysis to inform product design.

Facilitating connection, collaboration and knowledge sharing

Together we were able to drive the project forward to completion.

Leveraging our inhouse expertise, international connections with testing facilities and a deep understanding of national standards such as Eurocode 4 and AS/NZS 2327 to truly make a difference and fill the knowledge gaps.

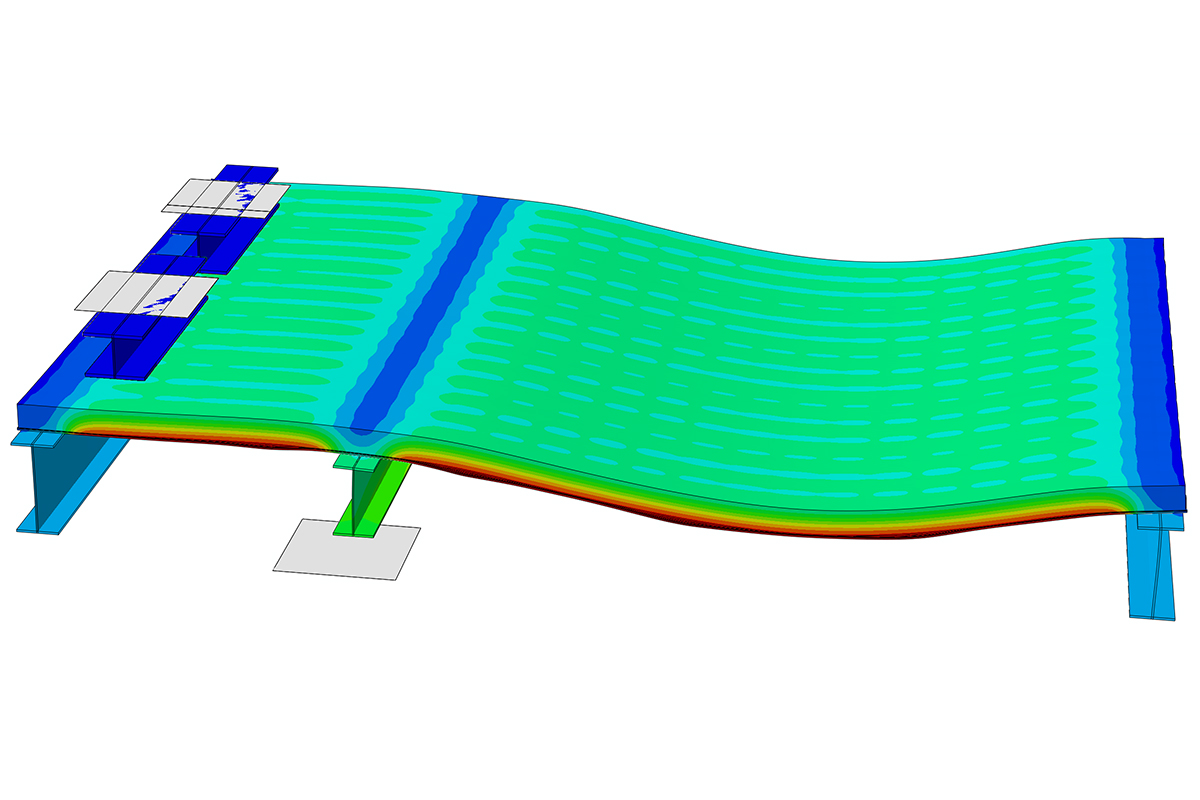

Our finite element capability proved much thinner slabs could be achieved than given in international standards to satisfy fire resistance requirements – allowing us to push design boundaries safely.

In addition, we showed that the traditional tension reinforcement bars in the bottom of the slab for the loadbearing capacity in fire could be removed completely – leading to a more cost-effective solution. The fire capabilities were subsequently validated by full-scale loaded fire tests undertaken at the world renowned Exova Warringtonfire testing facilities in the UK.

We were also able to take account of the non-linear behaviour in the double-span tests through the use of its Improved Engineering Method (IEM) to enable larger spans to be achieved. And, structural reliability analysis including Monte Carlo simulations, meant we were able to evaluate design values from the tests to ensure safety margins required by the NZBC were met. The ambient temperature design properties, full-scale non-composite and composite tests were undertaken at Imperial College London in the UK.

Welcome to the world ComFlor SR (well New Zealand anyway!)

We’re proud of the launch of the ComFlor SR product in New Zealand.

Not only has Steel & Tube created a new product range, but the design values have been adopted into the next version of their design software ComFlorTM. A move that will assist engineers in designing building floors with ComFlor SR product more efficiently and easily.

It reinforces that steel is an easy and versatile building material that continues to provide more choice to users. This combined with the products enhanced fire resistance, vibration and acoustic properties – makes it an attractive option in the important multi-storey residential sector – and we look forward to its uptake in the market.

Curious to know how we can help your product development?

Contact our General Manager Dr. Stephen Hicks, or Senior Structural Engineer Dr. Jing Cao.