At the beginning of the month, HERA was honoured to sponsor a presentation on cost effective fire solutions for steel structures in collaboration with the Auckland Structural Group.

We’ve found it’s a growing area of interest to many of our members and to the structural engineering fraternity.

Particularly as it’s been captured in the new Australasian multi-storey composite building design standard AS/NZS 2327:2017, where the latest advances in the fire design of composite concrete/steel structure components are comprehensively covered. This, coupled with the increasing use of structural steel framed construction, inspiring us to drive better understanding in this space.

Presented by Holmes Fire Technical Director Dr Linus Lim, and Principal Martin Feeney – it was well attended by over 70 people.

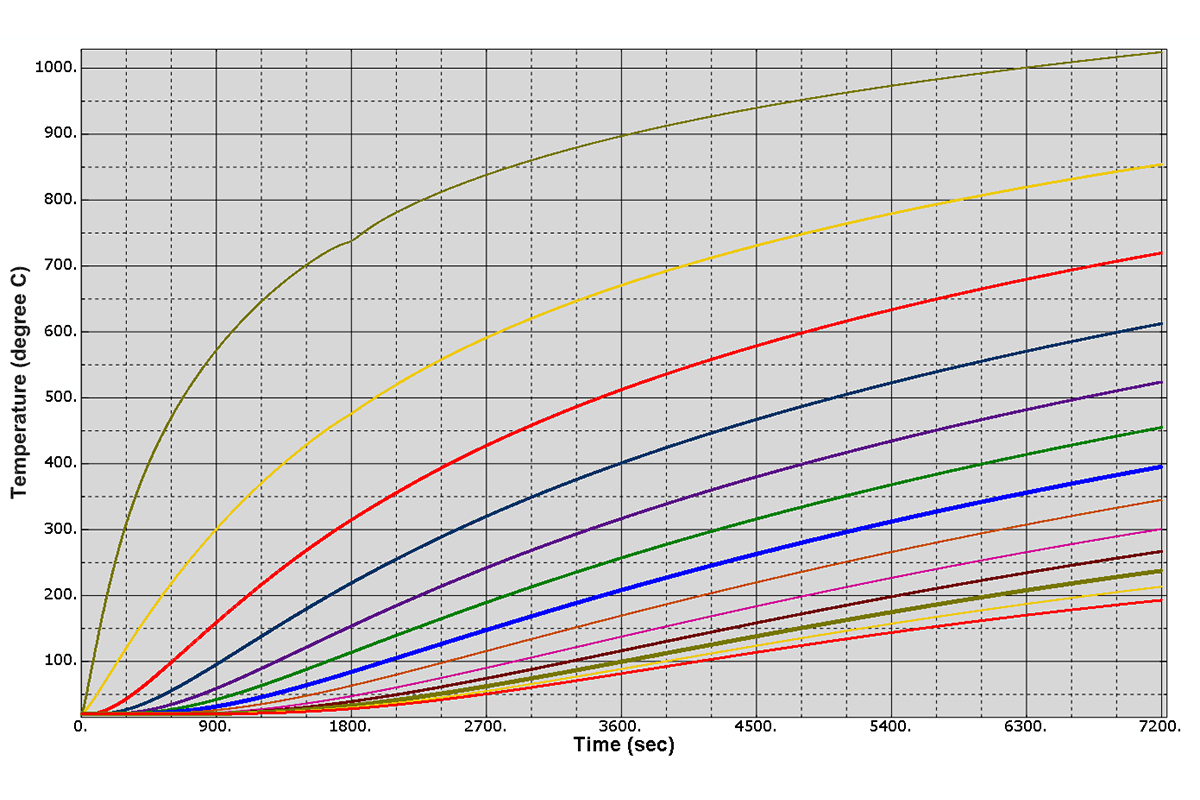

The presentation summarised material behaviour under elevated temperature, the most significant aspects professionals need to be aware of when designing steel structures for natural fire conditions, effects of fire, and more.

At HERA we believe it’s important to connect our industry with this type of technical knowledge. In an increasingly competitive materials market, it ensures NZ fabricated steel structures continue to be the safest building material choice not only in seismic events but fire conditions also.

Through these industry experts we helped attendees get a grasp of how to put to into use effective solution principles to maintain structural integrity in fire. Giving them insight into areas such as:

- the use of simplified structural design procedures,

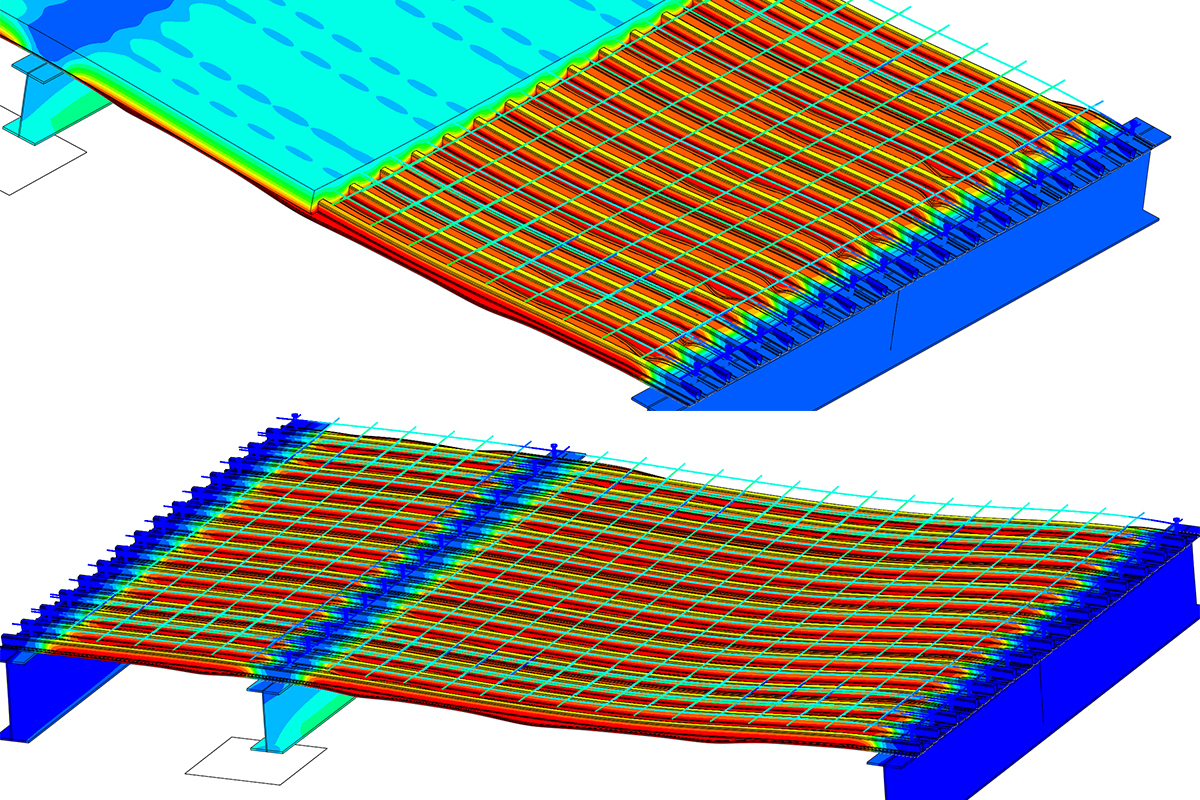

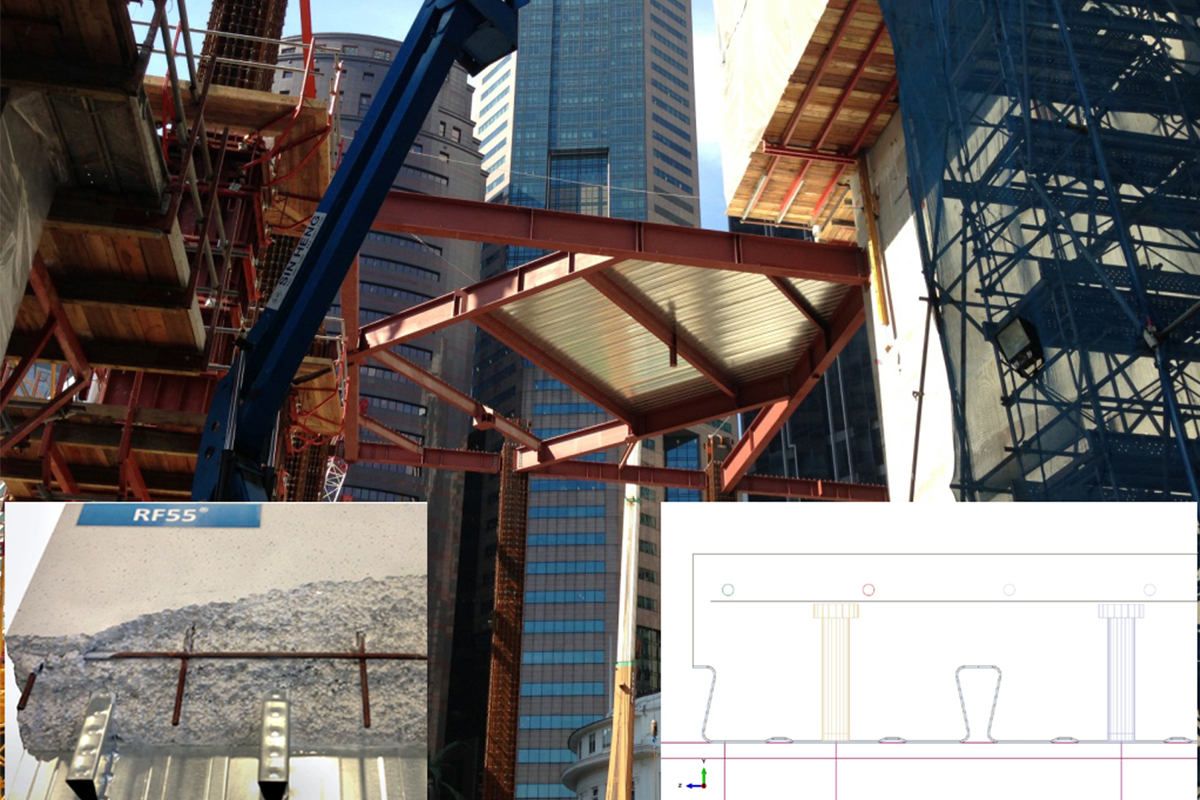

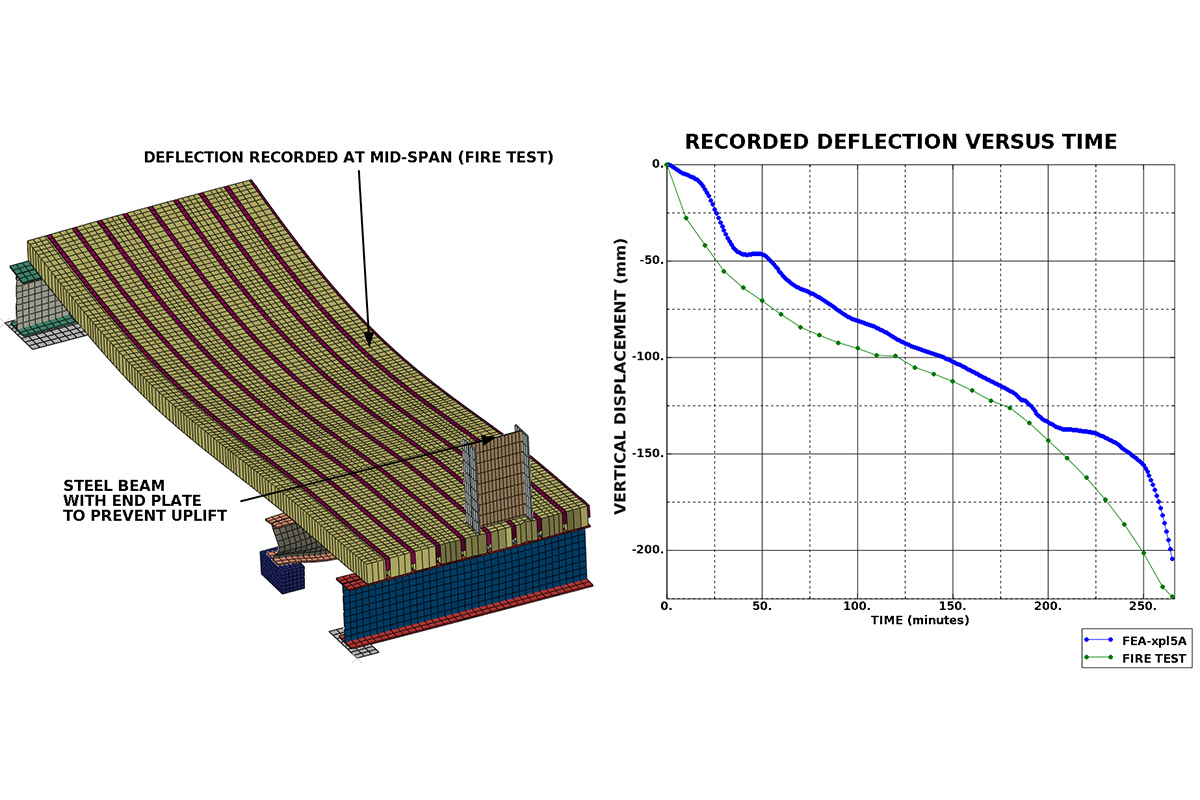

- creating cost savings through advanced non-linear simulations (finite element analysis) by eliminating applied fire protection on selective steel members, and

- eliminating unnecessary reinforcement and/or concrete slab thickness.

Our Structural Systems team was fully present, with our Finite Element Analyst Nandor Mago saying “This was a great evening which cemented the importance of our technical offerings in fire analysis.”

“We have a proven record in providing cost effective technical solutions both locally and abroad, saving our clients hundreds of thousand of dollars.”

“Looking back, we started from humble beginnings – assisting in experimental fire testing almost twenty years ago. Today, we’re now able to provide advanced sequentially-coupled thermal-stress fire simulations, and have published reports, conference and journal papers,” he said.

“I definitely recommend people get in touch with us if they have a fire related challenge they need to overcome!”

If you’d like to find out more about our FEA capabilities to assist with your fire design challenges, please contact our Finite Element Analyst Nandor Mago. We’re here to help!