- This event has passed.

Improve your business significantly with Bottleneck Analysis – June, Christchurch

June 12, 2019 @ 9:00 am - June 13, 2019 @ 5:00 pm

HERA | Bottleneck Analysis seminar | Christchurch | Limited seats available

12-13 June

About the event

This two-day workshop introduces the Theory of Constraints (TOC) concepts to attendees to give them a strong grasp of its application and potential.

Covering TOC for operations, project management, logistics and making financial decisions, this workshop is enhanced through practical case studies, and design templates for practical application.

After the workshop, we’ll also offer attendees the support to implement TOC concepts into their organisation via our trained HERA facilitators.

Why attend?

This workshop demonstrates how TOC can lift productivity through systems thinking – so you can significantly improve delivery time, production lead time, cost, quality and excellence.

TOC is a systems approach for the fabrication, construction, manufacturing, asset management and maintenance industries. It challenges some of the root beliefs that drives current measures and behaviours and offers powerful alternatives to existing methods.

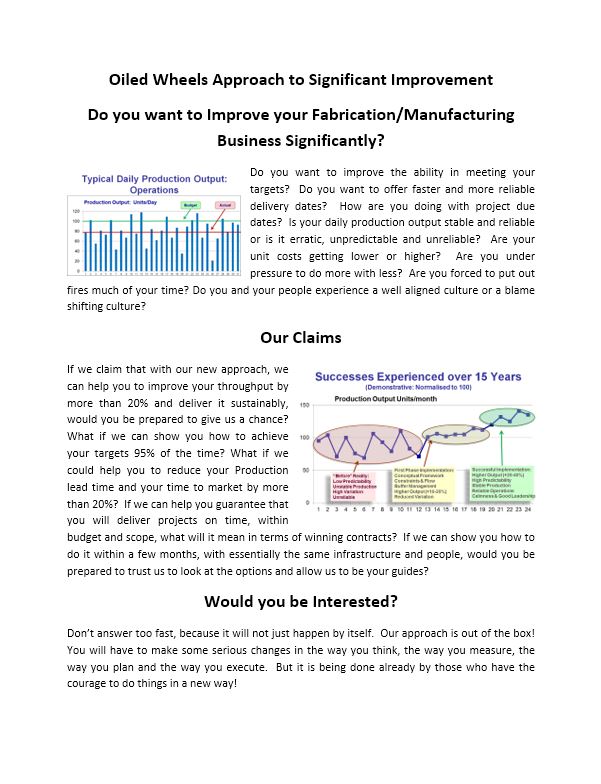

It’ll demonstrate why and how it’s possible for the same factory, infrastructure, people and equipment to produce at least 20% more by doing things differently. Ultimately, attendees will be challenged to change the way they think, plan, measure and execute their operations. The physical work will be the same, but the way it is streamlined will be different.

Significant improvements have been demonstrated around the world – and this shift and trend is growing rapidly. If you’re searching for significant value add achieved with far less stress and pressure for all – then this course is for you!

Who should attend?

This course is suited for Business and/or Operational Leaders; Financial, Planning, Training, Technical Services, Sales, People or Quality Assurance Managers; as well as Operational Supervisors.

| Day 1 | |

| 09:00 – 10:30 | TOC Frame of Reference – Variation and Interdependence in Operations.

– The TOC Framework & 3 Bottle metaphor – The impact of variation and interdependence – A new look at the common way of doing work – Understand the real cause of our problems – our thinking – A surprising conclusion.

|

| 10:30 |

Morning Tea

|

| 10:45 – 12:30 | Optimised Flow, Drum Buffer Rope, – the TOC solution for Operational Flow.

– Applying the systems approach to the business – A new way of setting up the organisation, a new way of planning & execution of operations – How to manage bottlenecks, focus activities and the flow of revenue – Buffers & protective capacity.

|

| 12:30 |

Lunch

|

| 13:00 – 14:30 | Critical Chain – the TOC solution for Project Execution.

– Understanding the biggest cause of poor project due date performance – Managing human behaviour to improve project execution – Dealing with the real cause of late delivery and how to finish projects faster than planned – Single projects and Multiple projects – Job shop environments

|

| 14:30 |

Afternoon tea

|

| 14:45 – 16:00 | Replenishment – the TOC solution for Supply Chain.

– Discovering the flaws of the typical forecasting system – Switching from Push to Pull systems – Replenishment on actual consumption & buffer management – Higher availability with lower stock levels – A proven alternative to forecasting.

|

| 16:15 – 17:00 | Finance & Measurements the TOC Way – Throughput Accounting.

– A new way of looking at managerial finances – An Alternative to the concept of product cost; revenue leverage – Identifying the leverage that determines flow of revenue. |

|

Arrie van Niekerk | Tavanec CEO

I have over 25 years’ experience with the application of the TOC Production Flow approach. My company has successfully applied it into more than 100 operations in many parts of the world, delivering remarkable results.

My expertise lies in finding unique solutions for production flow lines in manufacturing, fabrication, construction, asset management and maintenance – covering a range of activities related to iron and steel making, as well as iron ore, coal and other raw material mines.

Holding a B Eng Hons (Metallurgy) from the University of Pretoria I’ve been the Head of the Welding Research Facility for ISCOR Ltd rising to General Manager of Research and Development, and Works Manager of Iscor Refractories during my time there. Here I was able to implement TOC to reduce production lead time from 22 weeks with 60% on time performance to six weeks lead time with 92% on time performance over a nine month period.

Companies I’ve worked with as a specialist facilitator of TOC include Goldfields, Exxaro, Kumba Iron ore, Anglo American, Norilsk SA, Metorex, Kazakhmys, De Beers, Anglo Platinum, Avmin, Implats, Lonmin, Teal Exploration & Mining, Lonmin, Glencore.

“Our work has been valuable to 3M, AEL, Ampaglas, Anglo American, Arcellor Mittal, BLSA, De Beers, Exxaro, Goldfields, Implats, Kazakhmys, Kumba Iron Ore, Lonmin, Pharma Natura, Intercare and many other companies. Some have experienced up to 40% improvement in output within a matter of months.

$990

Platinum / Ordinary members

45% discount

$1,530

HERA Associate or Affiliate member

15% discount

$1,800

Non HERA member

Full price

- All prices are inclusive of GST

Want to get a HERA membership discount, but aren’t a member?

Find out how to become one today. Or contact our Manager Members Services and Support Brian Low for a chat.

Not only will this reduce your course fees for your business, but also for any of your employees throughout the year. And depending on the tier of membership you choose you can also enjoy discounts on offered resources and other membership benefits as well.

Address

John Jones Steel

18 Sir James Wattie Drive

Hornby

Christchurch

Bookings

Register today by simply filling out the onine form below and we’ll take care of the rest!

” Cut off date for registrations is Thursday 7th June”

I�m sorry � registration for this course has now closed.

We suggest you search our events section online to see if we�re holding this particular course in another location that would suit you. Alternatively, we can place you on a waitlist for the next available course.

To do so, please send an email to admin@hera.org.nz with subject title: Course waitlist request. Please include your full name, company, contact phone number, course and location you�re interested in within the email.