Attend this four series online course to get welder job knowledge validation to AS/NZS ISO 9606.1 (GMAW/FCAW) – all delivered by welding professionals.

During this course you’ll:

During this course you’ll:

Advantages of completing this training:

The Job Knowledge E-Training course is delivered as a series of online training modules.

Presenter

The standard specifies a range of quality requirements including qualification testing of welders. It requires welders to be qualified to AS/NZS ISO 9606-1 or AS/NZS 2980. The first option is the one preferred by industry as it isn’t industry-specific, meaning it can be utilised across a range of applications and industries, including the manufacture and repair of pressure equipment.

It requires that the test weld be made following a suitably qualified weld procedure (WPS), or draft procedure (pWPS). The procedure should be prepared in accordance with the application standards (AS/NZS 1554.1, AS/NZS 3992, ISO 15609-1, ASME IX etc.), and contain all requirements needed by the welder to reproduce the weld as specified within the appropriate application standard.

In order to successfully pass the (re)qualification test welders need to have adequate manual manipulation skills and job knowledge required to setup the job in accordance with the welding procedure (WPS).

Job knowledge requirements within AS/NZS ISO 9606-1 are optional, and whilst syllabus items are as defined within its Annex B, it’s noted that these items remain consistent with related standards such as AS 1796 theory syllabus, competency requirements. Welders who have successfully completed the existing AS/NZS ISO 9606-1 theory training, can usually be deemed to comply by the examiner.

The welder is a key part of the welding quality management system (QMS) to AS/NZS ISO 3834. He/she should be familiar with the key aspects of the system such as quality documentation, procedures and ITPs as well as individual inspection stages. The welder should be able to inspect his own work before Fabricator’s and third-party inspection. It includes visual checks to establish compliance of the weld with that required in the WPS and fabrication documentation. Introduction to welding QMS and welding inspection training for welders is included in this course as two separate modules.

It is recommended that the fabricators working under AS/NZS 5131 Construction Category CC3 and CC4 should employ welders with the Job Knowledge Test endorsement.

Automated and mechanised welding systems, where the required welding conditions are maintained by mechanical or electronic means but may be manually varied during the process are increasingly used in welding fabrication and manufacturing. The operators for these systems shall be qualified in accordance with ISO 14732. A functional knowledge test is compulsory according to ISO 14732 welding personnel – qualification testing of welding operators and weld setters for mechanized and automatic welding of metallic materials. This compulsory requirement can be fulfilled through HERA’s training.

This expert practical welder training has 20 modules, each consisting of:

The student workbook provides theory notes, detailed practical welding exercises and multi-choice questions for self-assessment corresponding to each topic.

The modules cover modern technology and emphasise safety, economical work practice and quality assurance as applied to welding fabrication. Industry welding standards e.g. AS/NZS 1554 series, ISO 3834, AS/NZS ISO 5817, AS/NZS 5131 and AS/NZS 1665 are introduced to ensure the relevance of the training.

Attendees seeking certification need to complete the online training and pass the online test. Upon successful completion of the training, an e-certificate HERA Job Knowledge Certificate AS/NZS ISO 9606.1 will be issued for each of the welding processes.

The validity of the certificate is 3 years. In order to extend the certificate a repeat test can be undertaken in the following 3-year periods.

$477

HERA Ordinary Member

(20% discount)

$567

HERA Affiliate or Associate members, SCNZ, Engineering NZ & SESOC members

(5% discount)

$597

Non-members

(full price)

*All prices include GST, and are for all four webinars.

Certification to HERA Job Knowledge Certificate AS/NZS ISO 9606.1 is available for each of the welding processes (that includes an online test).

This is an optional extra and incurs an additional charge of $100 which is NOT included in the webinar fees.

$100

Want to get a HERA membership discount, but aren’t a member?

Find out how to become one today! Or contact our Manager Customer Experience, Rebecca Symonds for more information.

Not only will this reduce your course fees for your business, but also for any of your employees throughout the year. And depending on the tier of membership you choose you can also enjoy discounts on offered resources and other membership benefits as well.

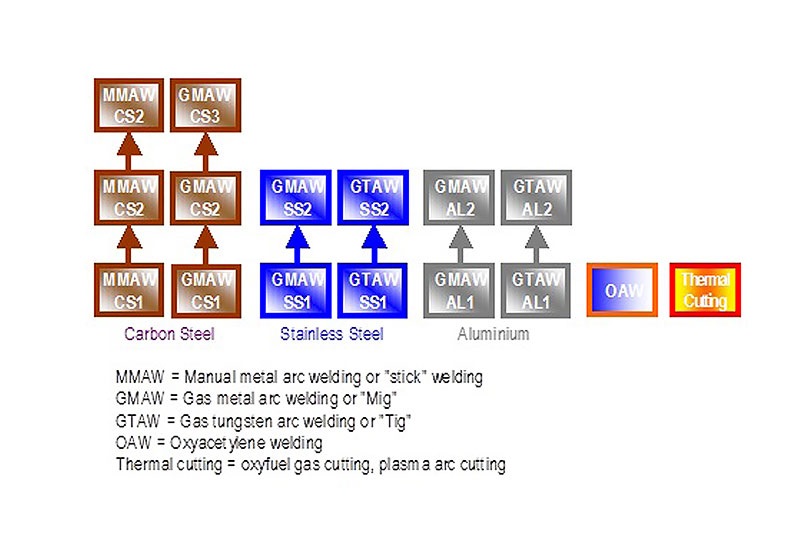

Here is our online training currently available: