A healthy sustainability solution for structural engineers: nothing is lost, nothing is created, everything is reused.

Traditionally, structural engineers have followed optimisation procedures to reduce material usage, increase the efficiency of designed systems, and consequently reduce negative environmental impacts.

Recently, a new procedure, termed ‘healthy sustainability’ has emerged, aimed at creating positive rather than reducing negative environmental impact. An example of a healthy sustainability approach is a building whose elements can be reused in the same or different project or product at any time under its operational service or at the end of life.

Reusing structural elements not only has the potential to significantly reduce embodied energy, but also addresses recourse limitation issues, and brings a cost-effective solution to construction value chains, governments, and end-user benefits.

Cradle to cradle to cradle

The strategy of healthy sustainability is cradle to cradle to cradle (C2C2C), while the strategy of conventional sustainability is cradle to grave. Fivet and Brutting (2020) define the C2C strategy as follow [1]:

footprint

lifespan

=

footprint

mass

+

mass

purpose

+

purpose

lifespan

(1)

This formula shows that extending the service of structural elements dilutes the material footprint. Reusing a structural element in different projects (with different functionality) can be continued forever (i.e. C2C2C∞).

Implementing the C2C strategy required development of a circular economy where “nothing is lost; nothing is created; everything is reused”, but where is this quote from?

Holistic design (also termed “design lead construction”), construction, manufacturing, monitoring and maintenance approaches are required, to transform the construction sector towards systematic adoption of C2C strategies [1].

Priority approaches to prevent and minimise waste in construction are to [1]:

1) reuse in the original system;

2) maintain or refurbish;

3) reuse in new systems; and

4) recycle or reprocess.

Options 1, 2, and 4 are globally common practices, whereas reusing structural elements in new contents (option 3) is rare.

Structural steel is reusable and can be recycled infinitely

Steel buildings are generally dismountable via reversible connections and therefore comparatively simple to re-use. It is possible to cut and reshape structural steel elements, which normally have predefined cross-sections and grades. Visual, acoustic, and load testing can also be used to determine the capacity of steel elements (Fivet and Brutting 2020) [1].

An example of strategies 1 and 2 in New Zealand practice is The Civic Administration Building (CAB) in Auckland. This former Council building was designed in 1956 and completed in 1966, and is one of the first structural steel-framed buildings in New Zealand. The total floor area of the CAB’s 18-storeys is 4600 sqm. While keeping its heritage prestige, CAB has been redesigned for functionality today, and is being restored and converted into high-end apartments. As the steel was in outstanding shape throughout the project, it required relatively minimal maintenance to ensure that it would meet Building Code requirements to survive for another 50 years.

Transformation to a circular economy requires both a C2C strategy and design for reconstruction, and the development of material passports is vital to facilitate the reuse of structural elements. Thus, material passports underpin transformation to a circular economy.

What is a material passport?

The concept of material passport was first published by Hansen et. al. (2012) where this idea was termed ‘Nutrient Certificates’ [3]: “Nutrient Certificates are collections of data that describe specific qualities of materials in products and provide value for their recovery and reuse”.

The purpose of the certificates is to create a market mechanism to encourage product designs, material recovery systems, and a chain of possession partnerships. This then improves the quality, value, and security of supply for materials so that they can be reused in continuous loops, closed loops, or beneficially returned to biological systems.

Material passports are sets of data that describe specific features of materials in products that give them value for recovery and reuse [4]. As a result, waste will be reduced, and fewer virgin resources will be used [5].

How is HERA incorporating this understanding into our research for industry?

We are currently developing a steel circularity passport to facilitate structural steel reuse.

This future-proofing project will create the first material passport in the Australasian construction sector, which will serve as a proof of concept to significantly assist the New Zealand construction sector to develop material passport capability for other building components and materials.

HERA’s steel circularity passport development is part of a broader HERA research program (Structures As Steel Banks (HERA-SASB) aimed at addressing broader research gaps and considering industry needs for even greater participation in the circular economy.

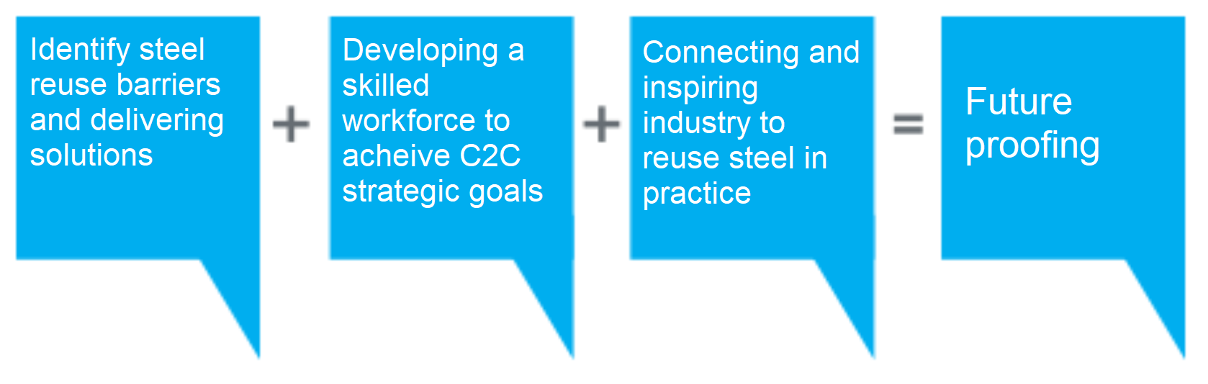

The HERA-SASB formula for success is illustrated below:

If you are interested to know more about our sustainability R&D and development of a steel circularity passport, please contact our General Manager Structural Systems, Dr Kaveh Andisheh.