The concept of a materials passport is a healthy sustainability solution for structural engineers. Nothing is lost, everything is re-created, everything is reused.

Traditionally, structural engineers have followed optimisation procedures to reduce material usage, increase the efficiency of designed systems, and consequently reduce negative environmental impacts.

Recently, a new procedure, termed healthy sustainability has emerged, aimed at creating positive rather than reducing negative environmental impact. An example of a healthy sustainability approach is a building whose elements can be reused in the same or different project or product at any time under its operational service or at the end of life.

Reusing structural elements not only has the potential to significantly reduce embodied energy, but also addresses recourse limitation issues, and brings a cost-effective solution to construction value chains, governments, and end-user benefits.

Research that drives #sustainablesteel

Material passports are sets of data that describe specific features of materials in products that give them value for recovery and reuse [1]. As a result, waste will be reduced, and fewer virgin resources will be used [2].

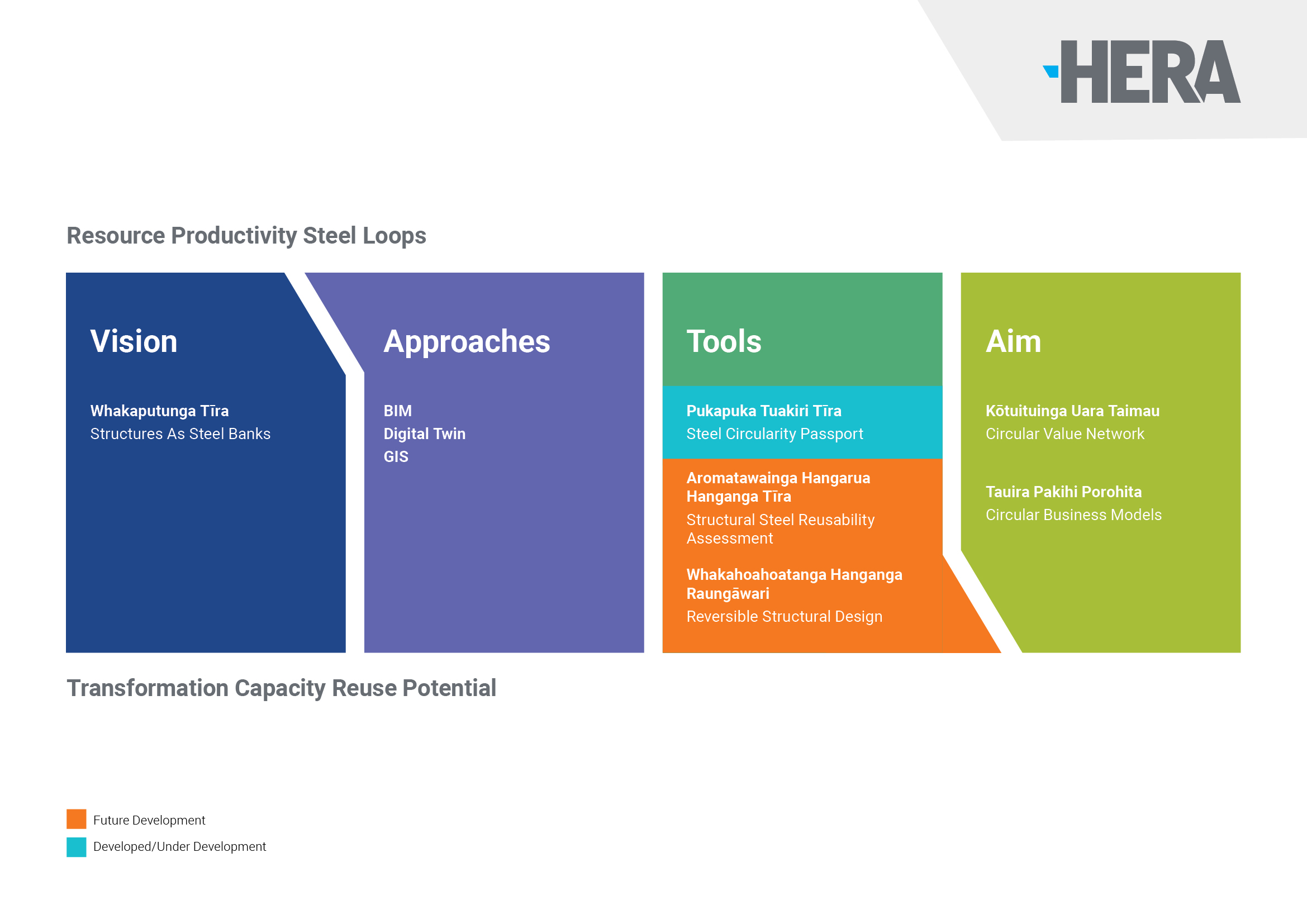

HERA is working to develop a steel circularity passport based on this principal in an effort to better facilitate structural steel reuse. This will be the first material passport in the Australasian construction sector of its kind, and serve as a proof of concept to significantly assist the New Zealand construction sector to develop material passport capability for other building components and materials.

This is based on a strategy of healthy sustainability – known as cradle to cradle to cradle (C2C2C). Implementing a C2C strategy requires the development of a circular economy [3], and transformation to a circular economy requires both a C2C strategy and design for reconstruction.

Priority approaches to prevent and minimise waste in construction are to [3]:

- reuse in the original system;

- maintain/refurbish;

- reuse in new systems; and

- recycle/reprocess.

Options 1, 2, and 4 are globally common practices, whereas reusing structural elements in new contents (option 3) is rare.

This is significant for the steel industry as structural steel is reusable and can be recycled infinitely. Steel buildings are generally dismountable via reversible connections and therefore comparatively simple to re-use. It is possible to cut and reshape structural steel elements, which normally have predefined cross-sections and grades. Visual, acoustic, and load testing can also be used to determine the capacity of steel elements [3].

This development is also part of a broader HERA research program (Structures As Steel Banks (HERA-SASB)) aimed at addressing broader research gaps and considering industry needs for even greater participation in the circular economy.