Your cart is currently empty!

Brittle fracture

Brittle fracture in metals poses a significant risk, as it can lead to sudden, catastrophic failure under low-stress conditions without warning.

This is particularly concerning for certain steel grades when exposed to specific temperature conditions, making it essential for design engineers to select materials that remain ductile under various stresses, including seismic actions and service temperatures.

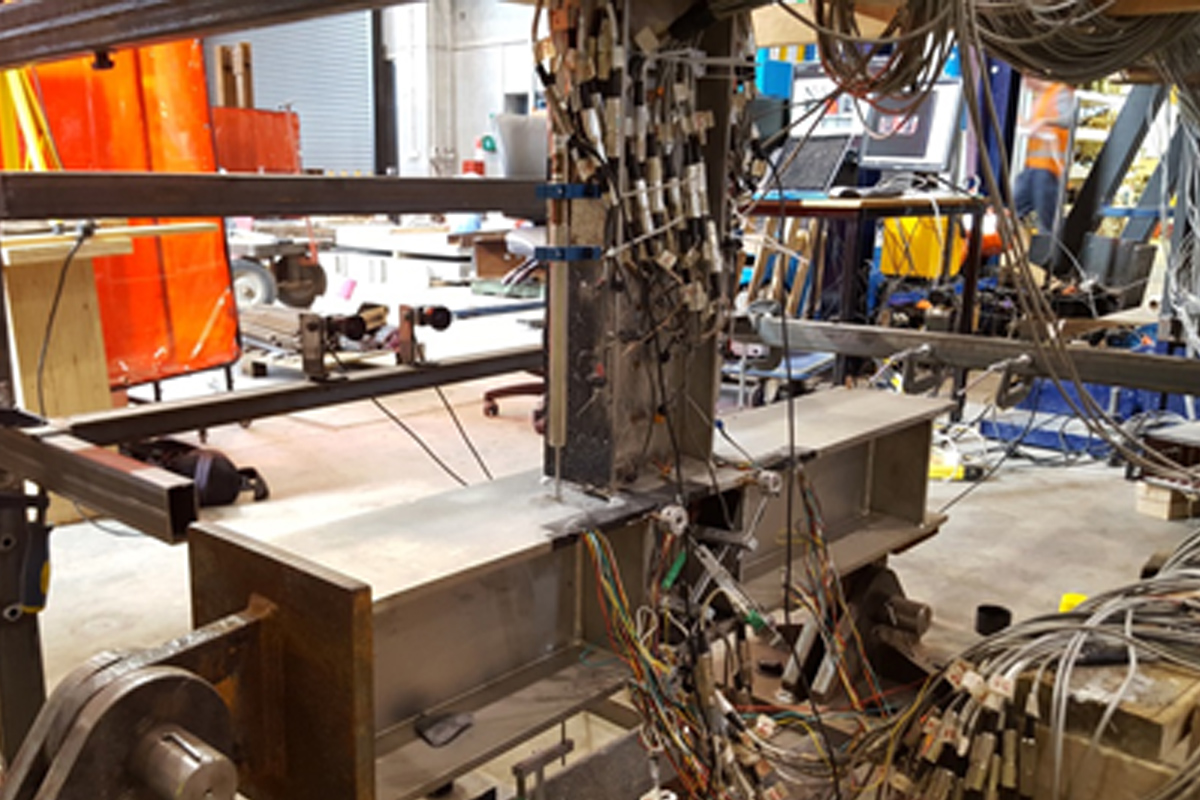

Our brittle fracture research focuses on developing procedures for selecting steel grades to meet relevant standards and ensure it is fit for purpose to keep steel structures safe and reliable throughout their service life.

Our projects

Brittle fracture provisions in standards

Developing procedures and recommendations to select steel grades.

The materials selection procedure in design standards AS 4100, NZS 3404.1 and AS/NZS 5100.6 were based on outdated test data on the notch toughness characteristics from a previous generation of steel products manufactured in Australia or Aotearoa. This procedure was also limited to temperatures down to -40°C and didn’t account for critical factors like welding, detailing stress utilisation, seismic loading rates, defects and similar.

In contrast, advanced methodologies such as EN 1993-1-10 “Material toughness and through thickness properties” considered these factors using fracture mechanics for more accurate material selection.

This approach has been adopted to develop updated selection requirements for AS/NZS steels in steel structures, in collaboration with the University of Wilhelmshaven and the University of Sydney. It is designed to withstand even cryogenic temperatures and includes New Zealand-specific requirements for seismic loading rates. It also offers recommendations for future updates to brittle fracture provisions in the steel structures design standards NZS 3404.1, AS/NZS 5100.6, and AS 4100.

Safety and resilience of steel structures

Key outcomes to ensure the safety of welded steel structures through brittle fracture prevention.

Brittle fracture is a critical failure mode that can compromise structural integrity, which is why selecting steel and welding consumables suitable for service conditions is paramount. While standards like NZS 3404 and AS/NZS 5100 guide material selection, they don’t cover all low-temperature applications or materials, leaving gaps in their applicability.

Our research program tackled these limitations by developing a new material selection method that extends beyond the constraints of current standards. Existing procedures, derived from earlier-generation steel products, are limited to temperatures as low as -40°C and fail to consider factors like welding effects, stress utilisation, seismic loading rates, and defects. The new method, grounded in fracture mechanics, significantly enhances resilience by addressing temperatures as low as -120°C while incorporating New Zealand-specific seismic loading considerations.

Key project outcomes include selection tables and recommendations that provide more accurate and less conservative guidance for plate thicknesses up to 75mm in non-seismic designs. These findings are informing the development of brittle fracture provisions for future Australian and New Zealand standards, including updates to NZS 3404. The method has already been applied to critical low-temperature projects, such as the New Zealand Antarctic Scott Base and railway bridge applications, enabling the use of alternative steels and LPI pipes.

The ongoing work extends to providing technical advice on material selection, welding consumables, and in-service inspections, as well as addressing seismic damage and fitness-for-service considerations. This research benefits from international collaboration with Professor Emeritus Adolf Hobbacher of Germany, leveraging global expertise to ensure robust and resilient steel structures.

Key publications: