Knowledge of welding residual stresses is important for assessing the safety, durability, and performance of welded structures.

It enables engineers to design, fabricate, and maintain structures that meet safety standards, perform well under load, and have a longer service life. Residual stresses can affect the stability of welded structures. High levels of residual stress can lead to distortion, warping, or buckling of the welded components, potentially compromising structural stability and safety. Residual stresses increase the susceptibility of welded joints to cracking.

While the effect of the residual stresses on the structures designed to the current standards and codes such as ASME, NZS 3404, AS/NZS 5100.6, AS4100 etc. has been already included in the safety concept, there are some emerging applications not covered by the standards yet. These applications include 3D-printed and complex geometries.

To keep HERA members up-to-date on this subject, we hosted a webinar Residual Stresses and Defects in Modern Welding and Additive Manufacturing on 20th September 2023. This webinar was brought by the Welding Innovations Network (WIN) which HERA is a part of.

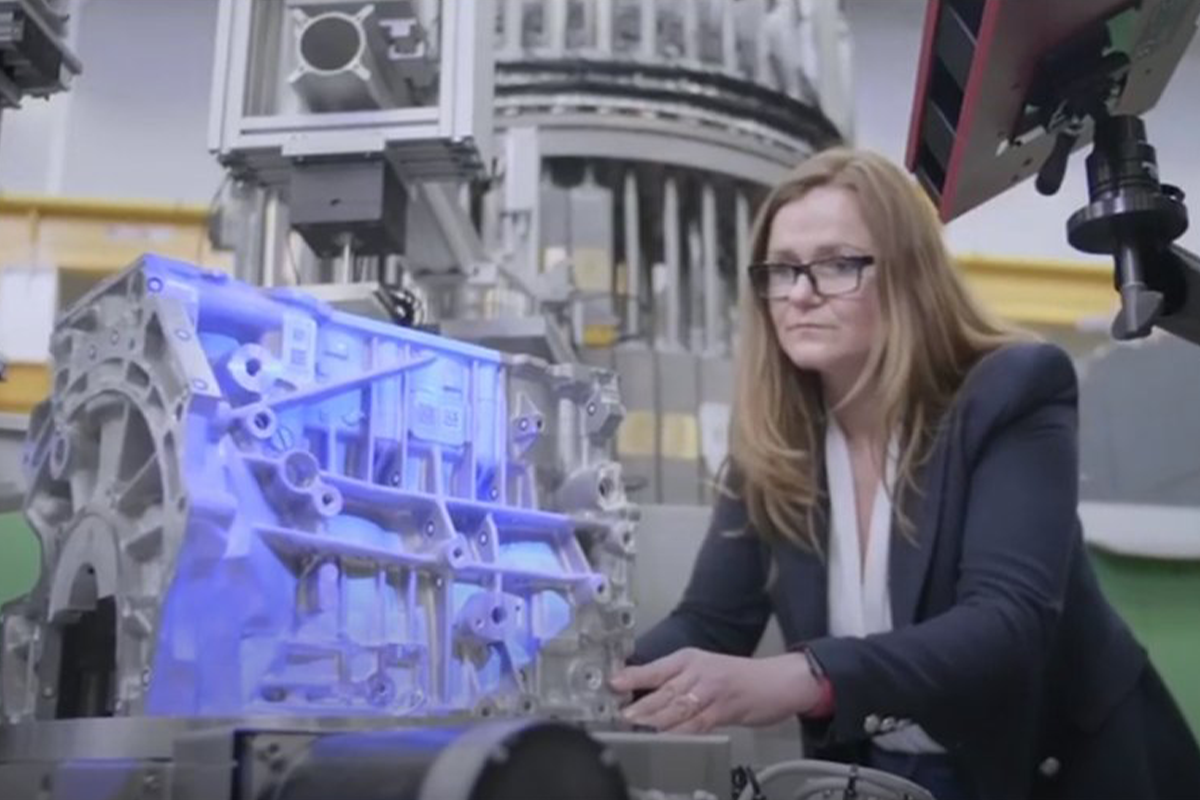

It was presented by Prof Anna Paradowska, an Industry Engagement Manager (since 2014) at the Australian Centre for Neutron Scattering (ACNS), Australian Nuclear Science and Technology Organisation (ANSTO) as well as Conjoint Professor in Advanced Structure Materials (since 2019) at The University of Sydney. Anna is an expert in neutron diffraction stress analysis and one of her goals in her research is to relate residual-stresses, and mechanical and metallurgical properties to manufacturing procedures and integrity requirements of engineering components, in particular in additive manufacturing and welded structures.

Anna covers several case studies in the field. Australian OPAL research reactor at ANSTO has several instruments available for materials science and engineering applications. The instruments have a unique non-destructive ability to determine critical imperfections and assist the performance of engineering apparatus via radiography and tomography (neutron imaging beamline DINGO), measure internal residual stresses and textures (neutron strain scanner KOWRI) in crystalline materials, such as metals, alloys, ceramics, and composites. These measurements can be carried out on real engineering components, mock-ups, or test samples with minimal preparation. This information provides a direct impact on the optimisation of modern manufacturing processes, improved product reliability, enhanced design performance, reduced production cost, and extended life prediction on significant engineering assets.

Over the years we have established a strong record in assisting Australian and New Zealand researchers across a wide range of engineering projects. The newly developed Australian Stress Engineering Centre at the University of Sydney is building on this experience and collaboration. HERA has been a collaboration partner with the University of Sydney on several research initiatives including welding technologies.

HERA members can contact the Welding Centre at HERA to discuss the development of possible R&D projects involving the above technologies.

Email: welding@hera.org.nz