We are pleased to announce that our paper “ A state of the art review of fillet welded joints” has been published and is available in the Journal of Materials.

Our PhD student, Dinesh Lakshmanan Chandramohan, is the main author of this article, supervised by Dr Krishanu Roy, Prof. James Lim from the University of Waikato, Dr Hafez Taheri and Dr Michail Karpenko, from HERA. The paper provides a comprehensive literature review of the performance of fillet welded joints under different loading situations to support and strengthen HERA Seismic Research Programme for its future research work.

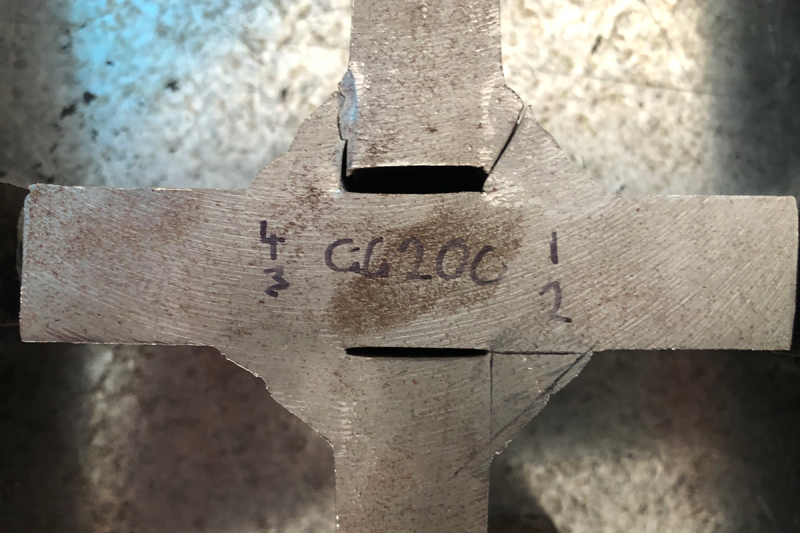

The experimental test photos related to finding fillet welds capacity as a part of the HERA Seismic Research Programme.

Fillet welded joints are commonly used in steel structures for a wide range of engineering applications such as in buildings, bridges, railways, ships, and in marine structures. These welded joints are often subjected to static and fatigue loading, resulting in failures of such joints. To this date, a number of experimental and numerical investigations on the strength and failure behaviour of fillet welded joints have been conducted, which are all available in the literature. This article aims to compile existing research on the static and fatigue strengths, and on thermal performance of fillet-welded joints in order to identify research gaps and gain a better understanding of their structural performance and failure mechanisms.

Over 100 papers published from 1970 to 2022, were critically reviewed. The existing design guidelines, experimental techniques, computational approaches, and research background were described for fillet welded joints under static, fatigue and fire loading. Various influencing factors on the structural behaviour of fillet welded joints including loading direction, weld geometry, plate thickness, filler material, steel grade, penetration depth, strength mismatch of the weld metal, post-weld treatment, and low and high cyclic loading are also summarized. Finally, the recommendations were mapped for future directions.

This article concluded that the use of filler materials, post-weld treatments, and penetration of weld metals could offer significant strength enhancements in terms of static and fatigue strength on fillet welded joints. In terms of thermal behaviour, it was found that the failure mechanism of fillet welded joints under both static and fatigue loading at elevated temperatures is still unclear. Hence, more experimental and numerical studies are required to better understand their structural performance. Furthermore, it was found that there is a lack of research on the fillet welded joints with the effect of root gaps and misalignments under static and fatigue loading conditions. Future research and design recommendations are required in this field, particularly for Australian/New Zealand standards. This article compiles research findings and research gaps in order to identify challenges and gain a better understanding of fillet welded joints for researchers and engineers in the welding community.

For more information, please contact hafez.taheri@hera.org.nz